Waterproof Board HDPE Geomembrane

Waterproof Board HDPE geomembrane- It is a variety of anti-seepage fabric made of polymer as the fundamental uncooked material, which can forestall liquid leakage and gasoline volatilization. It is broadly used in construction, transportation, subway, tunnel and engineering construction.

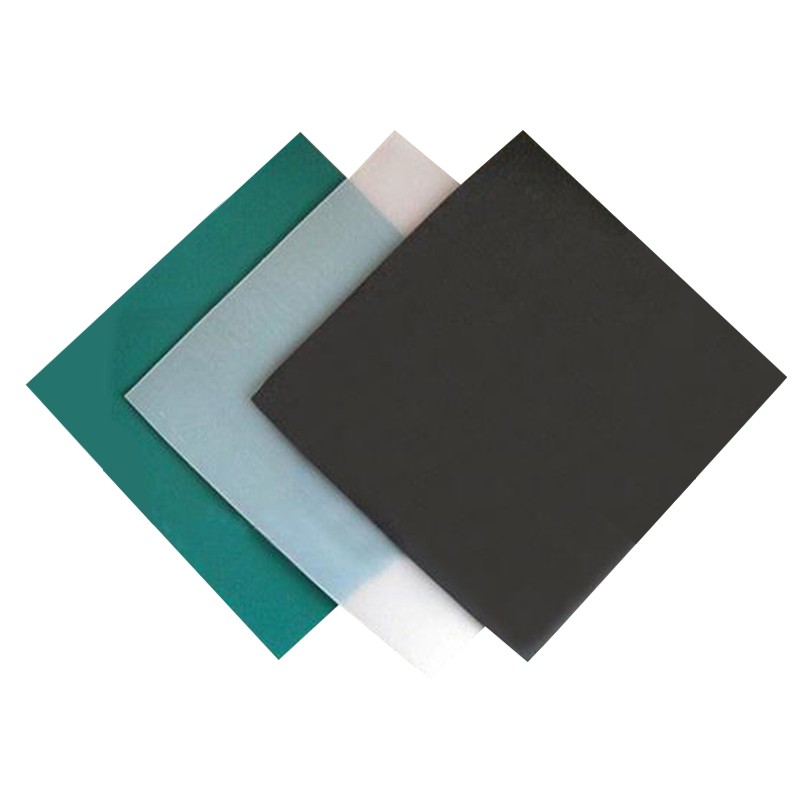

It is additionally referred to as geomembrane. It is generic to name a geomembrane with a thickness of ≥0.8mm as a water resistant board, and a geomembrane with a thickness of <0.8mm. It is a sort of anti-seepage fabric made of excessive molecular polymer as the primary uncooked material. Homogeneous flashing and composite flashing.

Waterproof Board HDPE Geomembrane

Waterproof Board HDPE Geomembrane (new HDPE water-resistant board) used in underground anti-corrosion and anti-seepage engineering is recombined on the foundation of normal water-proof board, the use of extremely good low-pressure high-density polyethylene uncooked materials, and scientifically proportioning carbon black, Aging agent, antioxidant, ultraviolet absorber, stabilizer and different auxiliary substances are made by using three-layer co-extrusion science with the most superior computerized geotechnical manufacturing gear in the world. This manufacturing line is fairly automated, from order input, formula, feed, processing to first-rate monitoring, all are entirely managed by means of computer, and are strictly operated in accordance to scientific data. And be capable to use the modern day uncooked substances at the equal time (with excellent tensile strength)

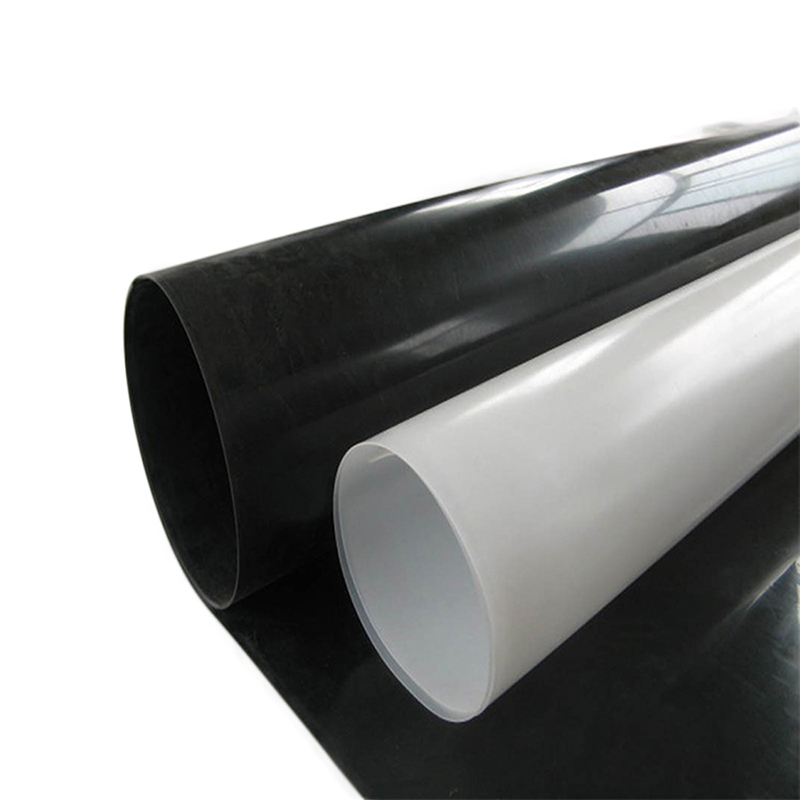

Product specification:

Thickness: 0.3-3mm; Width: 4-8m length according to user requirements.

Features:

Strength - under the same weight specification, the tensile strength in all directions is higher than other needle-punched non-woven fabrics.

Anti-ultraviolet light - has extremely high anti-ultraviolet ability.

Extremely high temperature resistance performance - high temperature resistance up to 230 ℃, and it still maintains structural integrity and original physical properties under high temperature.

Permeability and plane drainage - the waterproof board is thick and needle-punched, with good plane drainage and vertical water permeability, which can still maintain this performance after many years.

Creep resistance - the creep resistance of the waterproof board is better than other geotextiles, so it has good long-term performance. It is resistant to the erosion of common chemicals in the soil and the corrosion of gasoline, diesel, etc.

Extensibility - the waterproof board has a good elongation rate under a certain stress, so that it can adapt to uneven and irregular base surfaces.

Application:

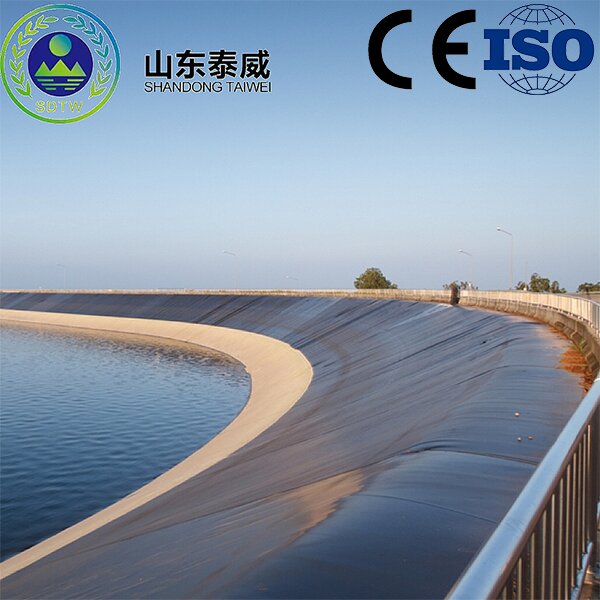

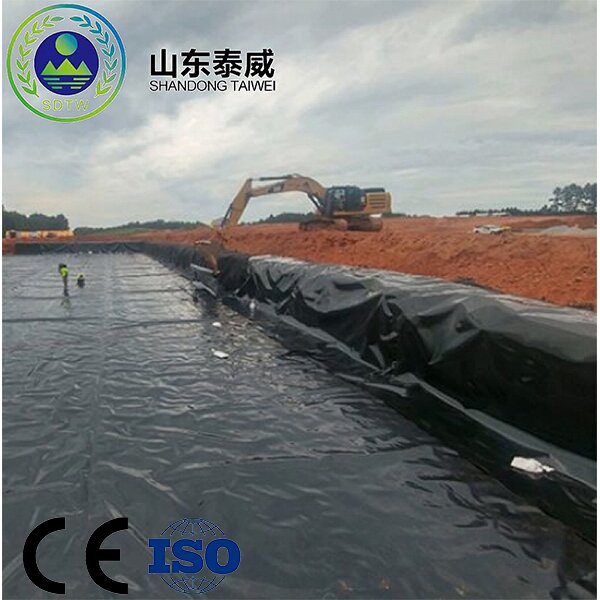

To prevent the leakage of liquid and the volatilization of gas, the function of waterproof board in rock engineering is mainly to prevent seepage and isolation, but it also plays the role of reinforcement and protection at the same time.

It is mainly used in anti-seepage of earth-rockfill dams, rockfill dams, masonry dams, concrete dams, tailings dams, sewage reservoir dams, channels, liquid storage tanks, anti-seepage lining of subways, basements and tunnels, road and railway foundations Anti-seepage, used with filament geotextiles, bentonite waterproof blankets and other geotechnical materials in sanitary landfills, etc.

Product Implementation Standards: America GRI GM-13 Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of Waterproof Board HDPE Geomembrane

Equipment of Waterproof Board HDPE Geomembrane

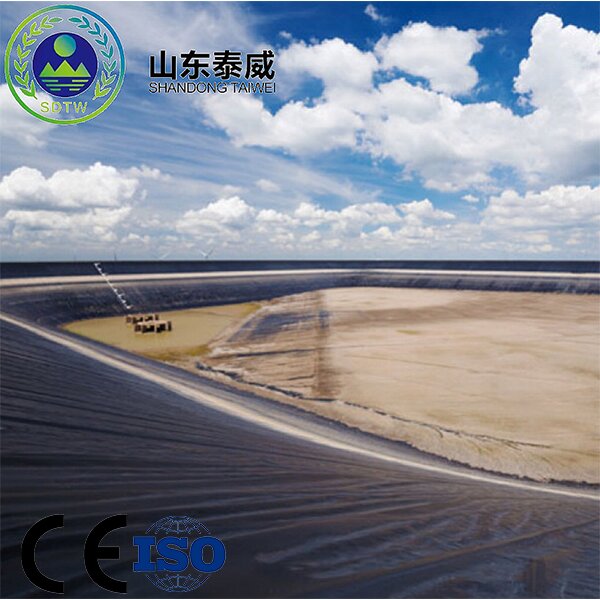

Usage Scenarios of Waterproof Board HDPE Geomembrane

Company Profile

Our business enterprise has mechanical equipment, technical personnel and a big manufacturing team. The annual manufacturing of geotextiles is greater than 30 million rectangular meters, and the composite geomembrane is increased than 10 million rectangular meters. The company will adhere to the working principle of "integrity-based, gratitude first", make friends from all over the world, cooperate and win-win, and are searching for common development.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |