Custom high strength Composite Geotextile

Custom high strength composite geotextile - 100g-800g composite Geotextile is used as the base material, and polyethylene, polyvinyl chloride and unique factors are used as the film. The composite geotextile of nonwoven material has the traits of one fabric one film, two fabric one film, two membranes one material and so on. The thickness of the geomembrane is 0.2-1.0mm, which has the feature of isolation, drainage, reinforcement, water seepage prevention, excessive flexibility, corrosion resistance and getting older resistance

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Custom high strength Composite Geotextile

Scope of application:

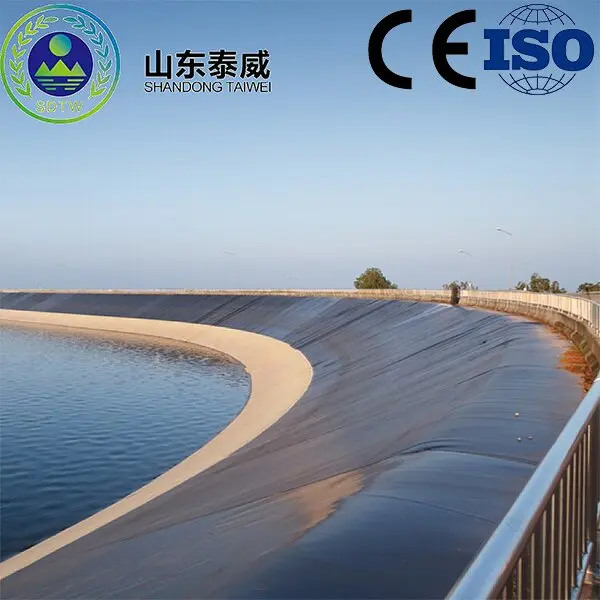

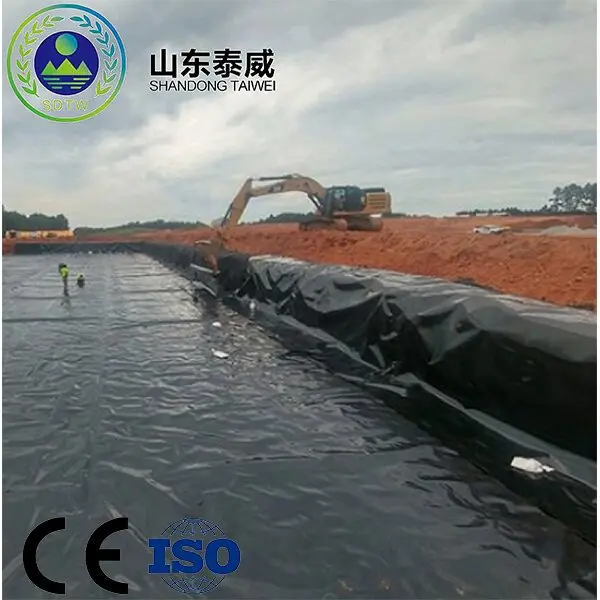

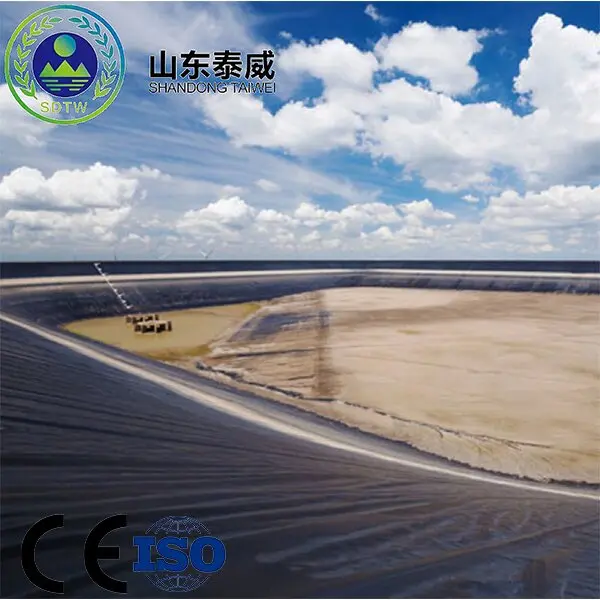

PET Composite Geotextile is an high-quality tightly closed material, extraordinarily proper for channel, drainage, guard, plain reservoir tightly closed reinforcement and rockfill dam and top notch water conservancy and internet site visitors tunnel purposes

One layer cloth with one layer membrane: material uint weight100~800gsm, membrane thickness: 0.l~l.0m

Two laver fabric with one laver membrane: material uint weiht 100~400gsm.membrane thickness: 0.2~1.0mm

One layer material with two layer membrane: material uint weight 100~800gsm , membrane thickness: 0.1~0.8mm

Product advantage

Custom high strength Composite Geotextile,Highway railway airport Composite Geotextile High strength, due to the use of plastic flat wire, in moist and dry prerequisites can preserve full electricity and elongation.

Corrosion resistance, in one of a kind pH degrees of soil and water can be lengthy corrosion resistance.

Water permeability is excellent between the flat wire gap, so it has excellent water seepage performance.

Good antimicrobial resistance to microorganisms, moth-eaten are now not damaged.

Construction is convenient, due to the fact the cloth is mild and soft, it is handy to transport, lay and construction.Good water permeability

Custom high strength Composite Geotextile,It is made of polymer substances with anti-aging agent brought in the manufacturing process. It performs nicely in unconventional temperature environment. Dikes, drainage ditches, waste yards and so on are excellent locations for it to show its skills. 2, the 2d is that this product has proper water filtration, no longer solely can be used for waterproof, however additionally has accurate drainage effect. Because of the sturdy extensibility of the uncooked substances used in its production. 3, water-resistant geotextile can be very robust adaptability to basis deformation, and in the unique building work, the operation is additionally very easy and convenient.

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Packing of PET Composite Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Geotextile constructing case

1. Use information rolling, the cloth ground have to be flat, and an wonderful allowance for deformation ought to be left.

2. The set up of long-filament or short-filament geotextiles typically adopts lap joints, stitching and welding. The width of stitching and welding is typically greater than 0.1m, and the width of lap joints is commonly more than 0.2m. Geotextiles that may additionally moreover be uncovered for a prolonged time want to be welded or sewn

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible