Thickness 0.1-1.0mm Composite Geotextile

Thickness 0.1-1.0mm composite geotextile -PET Geotextile is used as the substrate, and polyethylene, polyvinyl chloride and awesome elements are used asthe membrane. The composite geotextile of the non-woven fabric, has one material with one membrane,two fabric with one membrane, two menbrane with one cloth ect,Tensile, tear resistance, pinnacle breaking and one of a variety bodily and mechanical frequent ordinary overall performance signs and symptoms are high, the product has excessive strength, top notch extension performance, big deformation modulus, acid and alkali resistance, corrosion resistance, getting older resistance, proper anti-seepage widely wide-spread ordinary overall performance and so on

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Thickness 0.1-1.0mm Composite Geotextile Scope of application:

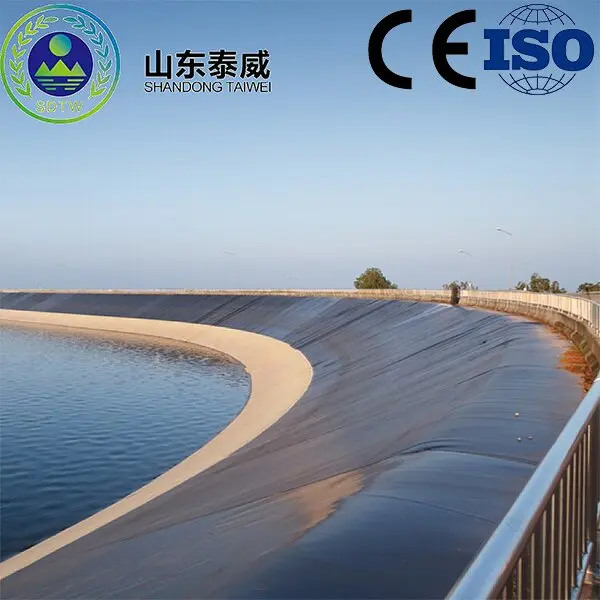

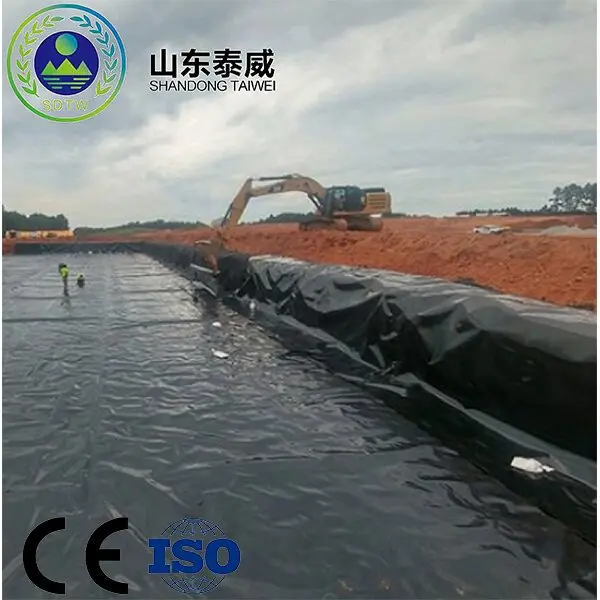

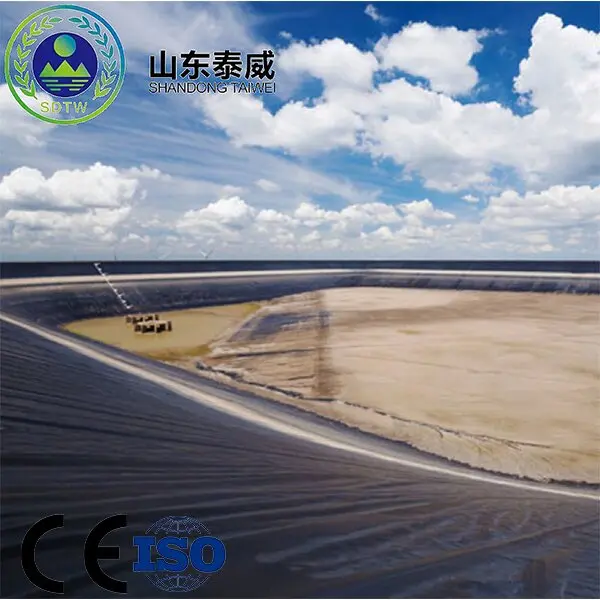

Water conservancy dam projectComposite Geotextile ,The choice of polymer supplies and the manufacturing system added anti-aging agent, so it can be used in unconventional temperature environment. It is regularly used for anti-seepage treatment of dykes, drainage ditches, and anti-fouling therapy of waste yards. Function: seepage prevention, isolation use: earth dam, rockfill dam, masonry dam and unfold pressure concrete dam; Horizontal anti-seepage masking in the the front of embankment and dam, vertical anti-seepage layer of foundation; Tailings dam, sewage storage dam physique and reservoir area; Construction cofferdam; The enormous software program of the composite geomembranes of channels and liquid storage ponds moreover performs a protective characteristic in the ecological environment.

Good bodily and mechanical properties

Water conservancy dam projectComposite Geotextile, Impervious isolation Composite GeotextileGeotextile as the protective layer of geomembrane, so that the defending tightly closed layer is no longer damaged. In order to restrict UV publicity and make greater anti-aging performance, it is super to use embedding method.Construction suggestion

Thickness 0.1-1.0mm Composite Geotextile, special attention should be paid to laying should not be too tight, not wrinkle, splicing should be firm. To strictly in accordance with the technical specifications of construction, good preparation, laying, splicing, inspection and backfill five quality pass. Due to the good anti-seepage effect of composite geomemofilm, it is widely used in the construction of water-saving reconstruction and extension supporting projects in Baojixia Irrigation area, which has been designed and constructed by the units

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Packing of PET Composite Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Geotextiles hold close the following three points:

Fabric look is carefully associated to cloth organization. Therefore, when deciding on knitwear, it is additionally indispensable to cautiously study the luster, color, and sample of the fabric. When pulling the cloth with each hands, appear at its longitudinal or horizontal elasticity and extensibility, and whether or not it is handy to deform; Weave, the area between the coils, whether or not it is free or tight, whether or not the deal with is gentle or rough, etc. In short, it is crucial to take a look at whether or not the cloth meets the simple necessities of the garment style, so as to acquire the impact of steady coordination between the look of the cloth and the fashion of the garment.

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||