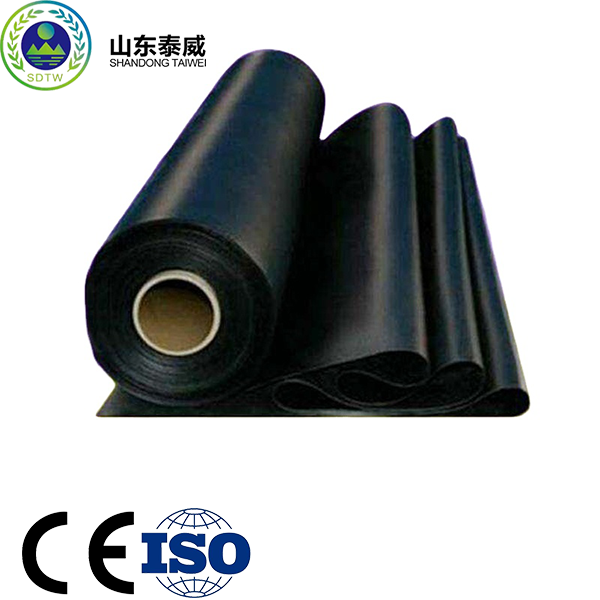

High strength pond liner dam impermeable geomembrane

HDPE geomembrane ;

Product specifications; Thickness; 0.3-3.0mm, width 1-8 meters, helps customization

Product characteristics; HDPE geomembrane has proper resistance to environmental stress cracking, big company temperature (-60-+60), and prolonged service existence (≥50 years)

Application scope; Merit in water conservancy, aquaculture, fish ponds, and so forth

High strength pond liner dam impermeable geomembrane

Product Introduction:

HDPE geotextile membrane, also known as high-density polyethylene geotextile, is a durable and versatile geosynthetic material used in various civil engineering and construction projects. It is made from high-density polyethylene, providing excellent strength and performance.

Features:

1.High tensile strength: HDPE geotextile membrane offers superior tensile strength, providing effective reinforcement and stabilization to the soil. It can withstand high loads and stresses, making it suitable for long-term applications.

2.Chemical resistance: The material exhibits excellent resistance to chemicals, acids, alkalis, and solvents. It can withstand exposure to aggressive substances, making it suitable for use in various environmental conditions.

3.UV resistance: HDPE geotextile membrane is treated with UV stabilizers, ensuring its resistance to degradation from prolonged exposure to sunlight. This provides long-term durability and performance in outdoor applications.

4.Excellent hydraulic properties: The fabric has excellent permeability, allowing water to pass through easily while retaining the soil particles. This promotes effective drainage and prevents water buildup or erosion in the soil.

5.Easy installation: HDPE geotextile membrane is lightweight and easy to handle, making it convenient to install in different construction projects. It can be easily cut and shaped to fit the required dimensions.

Application:

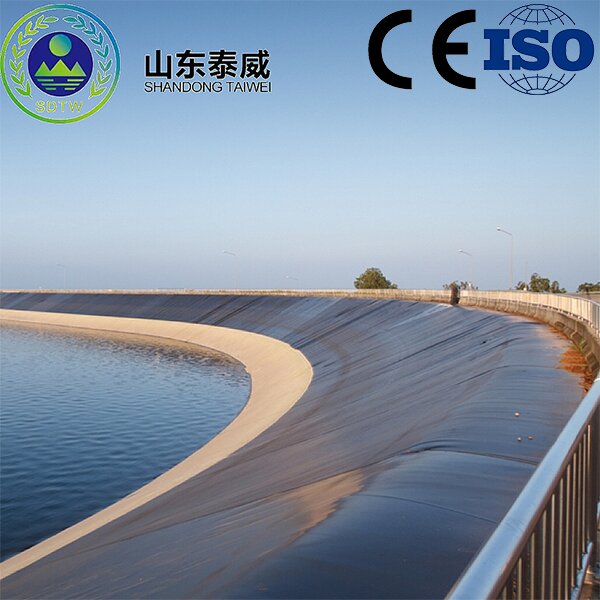

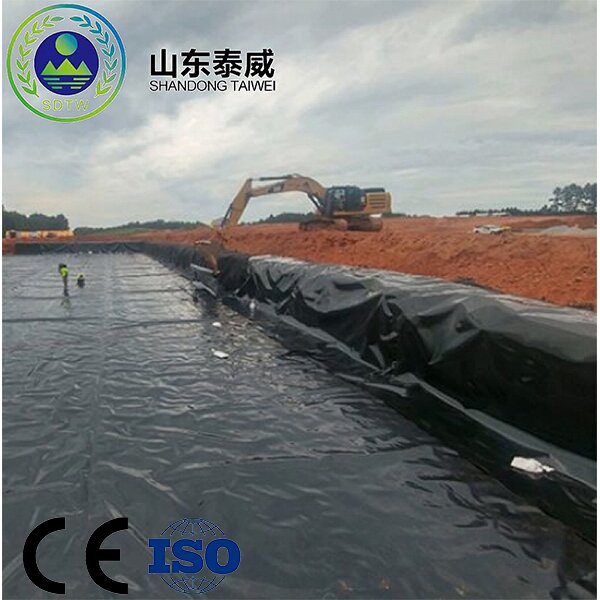

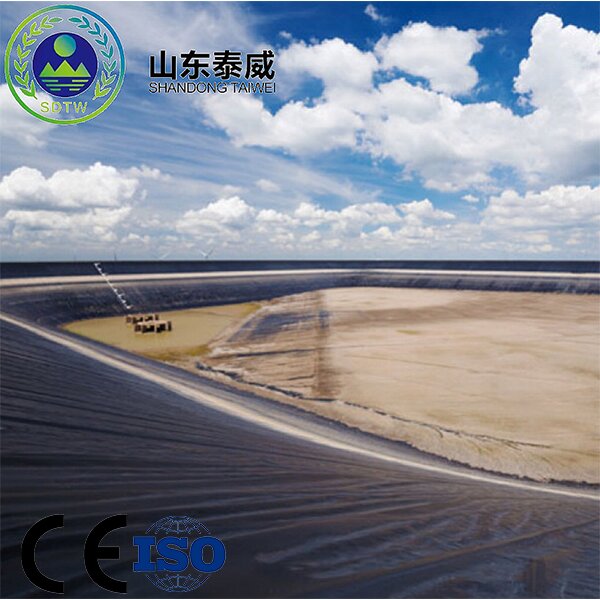

1.Pond and landfill liners: HDPE geotextile membrane is widely used as a liner in ponds, reservoirs, and landfills. It provides a barrier to prevent seepage and leakage, ensuring the containment of liquids and waste materials.

2.Retaining walls and embankments: The fabric is used in the construction of retaining walls and embankments to provide reinforcement and stability. It helps in distributing soil and water pressures, reducing the risk of wall failure.

3.Tunnels and underground structures: HDPE geotextile membrane is employed in tunnel construction to provide waterproofing and prevent water infiltration. It acts as a barrier, protecting the structure from moisture.

4.Agriculture and landscaping: The membrane is used in agriculture for lining irrigation canals and reservoirs to prevent water seepage and improve water efficiency. It is also used in landscaping projects for erosion control and stabilization of slopes.

5.Mining and containment: HDPE geotextile membrane is utilized in mining projects for tailings containment and heap leach pads. It helps in preventing the migration of contaminants and protects the surrounding environment.

Product Implementation Standards: America ASTM Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

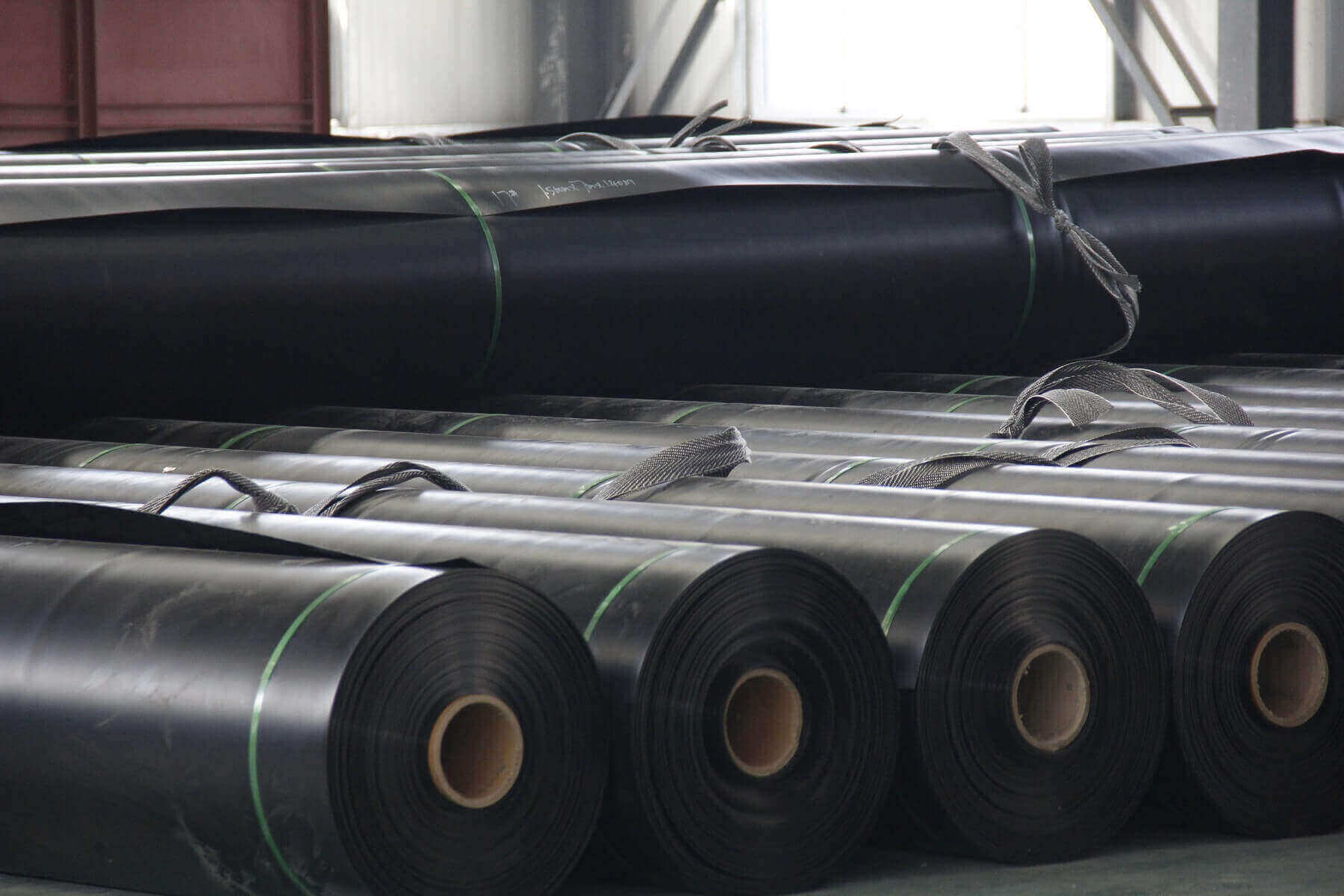

Equipment of High Quality Good anti-seepage performance HDPE geomembrane

Usage Scenarios of High Quality Good anti-seepage performance HDPE geomembrane

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |