Nonwoven Guard Fixed Composite Geotextile

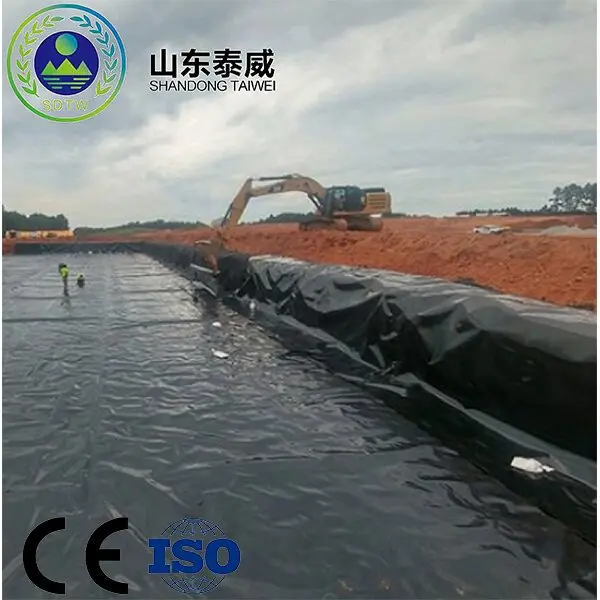

Nonwoven Guard Fixed Composite Geotextile -Geomembrane is best laid along a certain direction, both sides of the geomembrane are reserved for a certain PE film and PET bonding layer, laying to adjust the direction of each unit geomembrane, in order to facilitate the welding of two units of geomembrane. After the geomembrane is laid, it is necessary to press with sand bag to prevent wind movement, and the edge joint is not required to have dirt, water, dust, etc.

Before welding, we should adjust the two edges of the joint PE single film, so that the lap of a certain broadband, and smooth, no wrinkle.

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Nonwoven Guard Fixed Composite Geotextile

Scope of application:

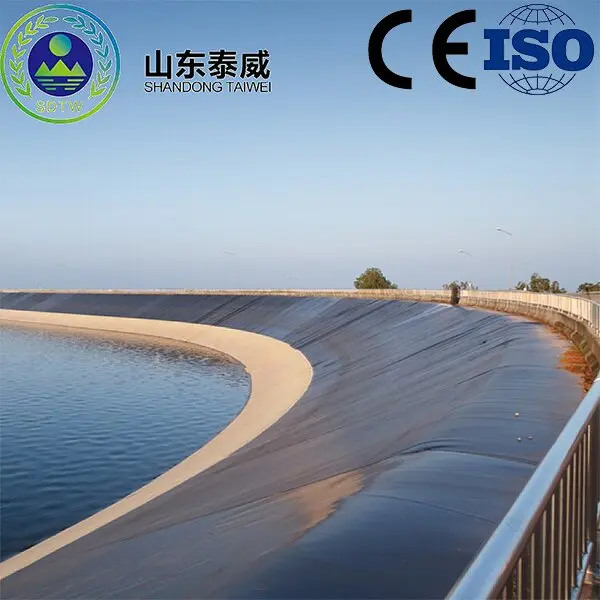

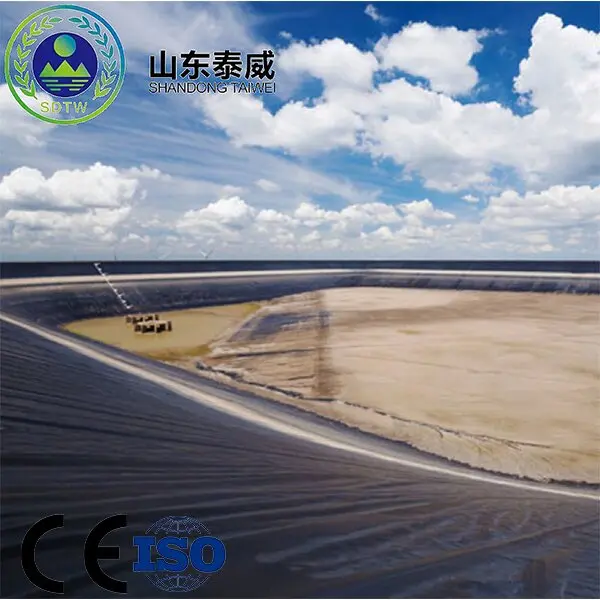

Water conservancy dam projectComposite Geotextile ,The preference of polymer elements and the manufacturing gadget delivered anti-aging agent, so it can be used in unconventional temperature environment. It is usually used for anti-seepage remedy of dykes, drainage ditches, and anti-fouling remedy of waste yards. Function: seepage prevention, isolation use: earth dam, rockfill dam, masonry dam and unfold strain concrete dam; Horizontal anti-seepage protecting in the the the front of embankment and dam, vertical anti-seepage layer of foundation; Tailings dam, sewage storage dam physique and reservoir area; Construction cofferdam; The considerable software program application of the composite geomembranes of channels and liquid storage ponds in addition performs a shielding attribute in the ecological environment.

Good bodily and mechanical properties

Nonwoven Guard Fixed Composite Geotextile,Water conservancy dam projectComposite Geotextile, Impervious isolation Composite GeotextileGeotextile as the defensive layer of geomembrane, so that the defending tightly closed layer is no longer damaged. In order to preclude UV publicity and make higher anti-aging performance, it is excellent to use embedding method.Construction suggestion

Nonwoven Guard Fixed Composite Geotextile,Thickness 0.1-1.0mm Composite Geotextile, specific interest have to be paid to laying must now not be too tight, now not wrinkle, splicing need to be firm. To strictly in accordance with the technical specs of construction, appropriate preparation, laying, splicing, inspection and backfill 5 fine pass. Due to the exact anti-seepage impact of composite geomemofilm, it is extensively used in the building of water-saving reconstruction and extension aiding tasks in Baojixia Irrigation area, which has been designed and developed by using the units

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Packing of PET Composite Geotextile

You can freely pick out PE movie or PP woven bag for outer packaging, and there are paper tubes of exclusive sizes interior the product for you to select freely.

Geotextiles keep shut the following three points:

Fabric appear is cautiously related to material organization. Therefore, when determining on knitwear, it is moreover quintessential to cautiously learn about the luster, color, and pattern of the fabric. When pulling the material with every hands, show up at its longitudinal or horizontal elasticity and extensibility, and whether or not or no longer it is accessible to deform; Weave, the location between the coils, whether or not or no longer it is free or tight, whether or not or no longer the deal with is mild or rough, etc. In short, it is critical to take a appear at whether or not or no longer the material meets the easy necessities of the garment style, so as to accumulate the influence of constant coordination between the seem to be of the material and the trend of the garment.

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||