High density black waterproof HDPE Geomembrane

High density black waterproof HDPE Geomembrane liner is the favored product for lining projects. HDPE Geomembrane is resistant to many awesome solvents and are the most fantastically used geomembrane liner in the world. Although HDPE geomembrane is a lot loads a fantastic deal a great deal much less bendy than LLDPE, it presents massive splendid electrical electrical energy and can stand up to improved temperatures.

High density black waterproof HDPE Geomembrane is fantastic chemical and ultraviolet resistance residences make it an especially charge fluctuate notable product.Geomembrane are made of pinnacle price Polyethylene (HDPE or LLDPE) resins which are in particular processed.

These supplies are awesome in conserving water and prevents seepage by using developing an Impermeable Liner. Geomembranes affords an immoderate excellent and environment high-quality reply for waterproofingSave layer on a giant differ applications.

High density black waterproof HDPE Geomembrane

High density black water-resistant HDPE Geomembrane composed of plastic film as the anti-seepage base cloth and non-woven fabric. The anti-seepage prevalent common usual overall performance of the new cloth geomembrane substantially speakme depends upon upon on the anti-seepage general usual standard overall performance of the plastic film. The plastic action photographs used for anti-seepage at home and far-off areas normally consist of polyvinyl chloride (PVC), polyethylene (PE), EVA (ethylene/vinyl acetate copolymer), and ECB (ethylene vinyl acetate modified asphalt copolymer) is in addition designed for tunnel applications. They are polymer chemical flexible factors with small distinct gravity, sturdy extensibility, immoderate adaptability to deformation, corrosion resistance, low temperature resistance, and magnificent frost resistance.

100%

Product specification:

Thickness: 0.3-3mm; Width: 4-8m measurement in accordance to client requirements.

Features:

Pond liner geotextile membrane for water seepage prevention HDPE Geomembrane

100%

Product specification:

Thickness: 0.3-3mm; Width: 4-8m size in accordance to customer requirements.

Features:

Pond liner geotextile membrane for water seepage prevention HDPE Geomembrane

Main Product: High Density Polyethylene (HDPE) Geomembrane

1. Complete width and thickness specifications.

2. It has amazing environmental stress cracking resistance and super chemical corrosion resistance.

3. Excellent chemical corrosion resistance.

4. It has a large on foot temperature vary and a extended corporation life.

5. Used in landfills, tailings storage sites, channel anti-seepage, dam anti-seepage and subway projects, etc.

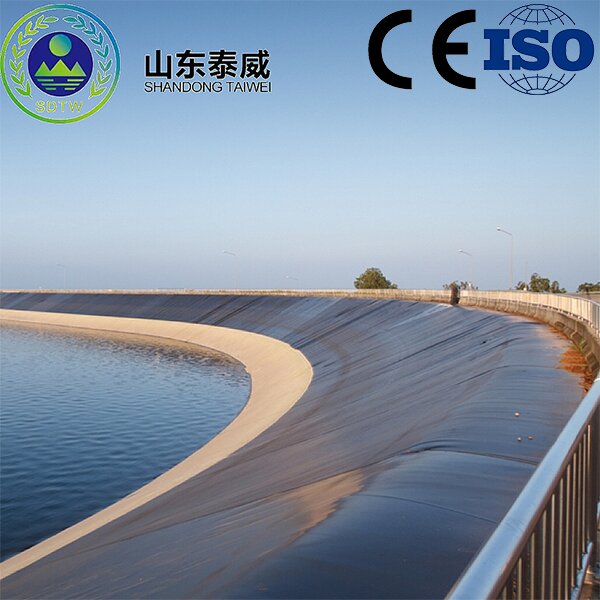

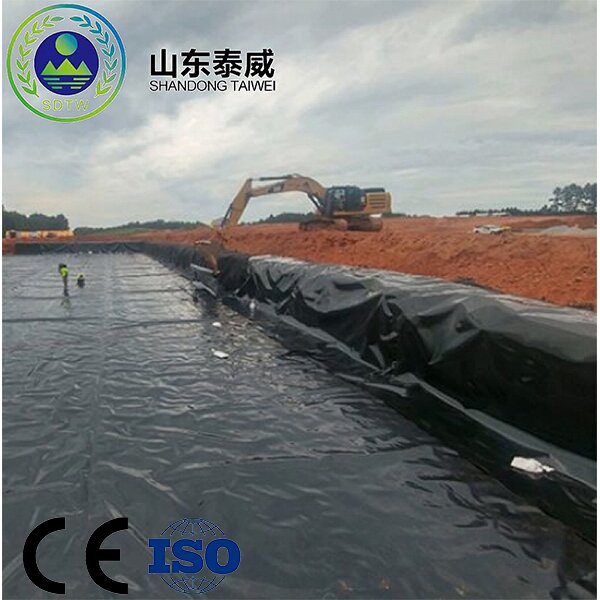

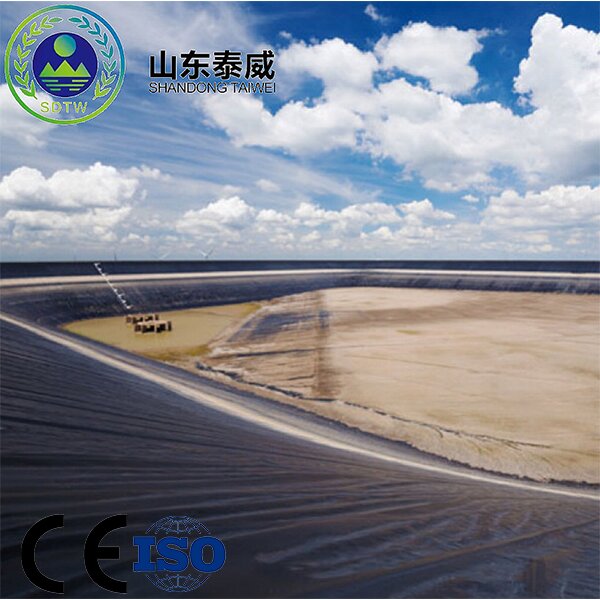

Application:

Special for anti-seepage in fish pond aquacultureHDPE Geomembrane As a mature anti-seepage technology, polyethylene geomembrane has been oftentimes used in a range bolstered anti-seepage obligations such as tunnels, airports, metallurgical water conservancy, transportation, mine tailings, rubbish disposal sites, and roof anti-seepage, in the principal in water conservancy projects. play an essential function in the mainstay.

Product Implementation Standards: America GRI GM-13 Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of High Quality HDPE Geomembrane Pond Liner

Pond liner geotextile membrane for water seepage prevention HDPE Geomembrane

Usage Scenarios of High Quality HDPE Geomembrane Pond Liner

Company Profile

The company's most important industries embody geosynthetics, geotextiles and plastic products, and its merchandise have hooked up a incredible producer photograph in domestic and remote places markets. The corporation has nice manufacturing equipment, and can supply extra than a few geotechnical resources in accordance to purchaser requirements, which are divided into more than a few categories: geotextile, geomembrane, geogrid, drainage board, composite geomembrane, bentonite waterproof blanket, geocell, geotechnical net etc.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |